The 8 Best Things About Plastic Pipe End Cap

- Plastic pipework is used for the conveyance of drinking water, wastewater, chemicals, heating fluid, and cooling fluids, foodstuffs, ultra-pure liquids, slurries, gases, compressed air, irrigation, plastic pressure pipe systems, and vacuum system applications.

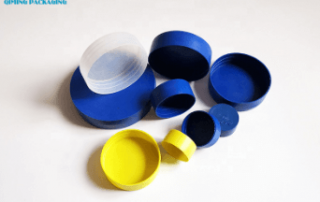

2.Pipe Cap.

Pipe caps act as protective devices and are designed to protect pipe ends of various shapes. The main purpose of using pipe caps is to waterproof the connections. They are also used to close the ends of hydraulic or pneumatic pipes and tubes.

3.The material of the plastic pipe.

Polyethylene or PE is a tough thermoplastic material. PE piping is used for a broad range of pressure applications including the transportation of drinking water and natural gas, irrigation, sewers, and drainage lines.

4.PE has been used for pipes since the early 1950s.

PE pipe is made by extrusion in a variety of size dimensions. It is lightweight, flexible, and easy to weld. Its smooth interior finish ensures excellent flow characteristics. Continuous development of the material has therefore enhanced its performance leading to rapidly increasing usage by major water and gas utility companies throughout the world. The weldability allows to either butt-weld or electrofuse weld the pipes too long lengths and thereby secure robust joints

5.The pipes are also used in the lining and trenchless technologies, the so-called no-dig applications where the pipes are installed without digging trenches and disrupt the activities above ground. Here the pipes may be used to line old pipe systems to stop leakage and improve water quality. These ingenious solutions are therefore helping engineers to rehabilitate pipe systems made of traditional materials. Excavation is minimal and the process is carried out quickly below ground.

6.The later years the PE materials have been developed with new properties. One example is PE-RC which has an extra high resistance against crack propagation and is therefore suited for no-dig installations with a potential risk of scratching the pipes when pulling it through the ground or through an old and leaking cast iron pipe. Furthermore, the PE-RC material allows the use of existing backfill material instead of sand when pipes are installed in the ground.

7.Also for PE pipe material, several studies demonstrated the long track record with an expected lifetime of more than 100 years.

8.Qiming’s extensive line of flange covers includes the following three styles with over 80 sizes. Most covers are in stock for immediate shipment.

Our All-Around ANSI Flange covers provide complete all-around flange protection, easy to fit, durable, and flexible. They are offered in yellow flexible polyethylene and protect both the full face and raised face of the flange. No fasteners required.

If you are interested in us, contact us now to get more detail!

Mobile/Whatsapp: 86-15324051286

Company email: packaging@qimingpackaging.com

If you do not find the products you want, you can click another website: https://www.qiminggroup.com/products/plastic-flange-covers/