1. What is the PVC?

PVC, the full name of Polyvinylchloride, the main component is polyvinyl chloride, and other ingredients to enhance its heat resistance, toughness, ductility and so on. The uppermost layer of this surface film is lacquer.

The density of pure polyvinyl chloride is 1.4 g/cm3, and the density of polyvinyl chloride plastic parts to which plasticizers and fillers are added is generally 1.15-2.00 g/cm3.

Hard PVC has good tensile, flexural, compressive and impact resistance properties and can be used alone as a structural material.

The softness, elongation at break, and cold resistance of the soft polyvinyl chloride increase, but the brittleness, hardness, and tensile strength are lowered.

Polyvinyl chloride has good electrical insulation properties, can be used as a low-frequency insulation material, and its chemical stability is also good. Due to the poor thermal stability of polyvinyl chloride, long-term heating will cause decomposition, release HCl gas, and discolor the polyvinyl chloride. Therefore, its application range is narrow, and the use temperature is generally between -15 and 55 degrees.

PVC is polyvinyl chloride, a plastic product synthesized from 43% oil and 57% salt. Compared with other types of plastic products, PVC is more effective in the application of raw materials, reducing fuel consumption. At the same time, the energy consumption of the PVC manufacturing industry is also very low. And in the later stages of the use of PVC products, it can be recycled and converted into other new products or incinerated to obtain energy.

2. Features of the PVC

Molding shrinkage: 0.6-1.5%, molding temperature: 160-190 ° C, melting point 212 ° C.

Excellent mechanical properties, excellent electrical properties, strong acid and alkali resistance, good chemical stability, but low softening point. Suitable for making thin plates, wire and cable insulation, seals, etc.

Molding characteristics

-

Amorphous material, low moisture absorption, poor fluidity. In order to improve fluidity and prevent bubbles, the plastic can be driedin advance. The mold casting system should be short and thick, the gate section should be large, and there should be no dead angle. The mold must be cooled and the surface should be chrome-plated;

-

Due to its corrosive and fluid characteristics, it is best to use special equipment and molds. All products must be added with different types and amounts of additives as needed;

-

It is easy to decompose. It is more easily decomposed with steel and copper at 200 °C, and it escapes corrosion when decomposed. Irritant gas. The molding temperature range is small;

-

When using the screw injection machine nozzle, the hole diameter should be large to prevent dead angle stagnation. It is best not to have inserts, if there is an insert, it should be preheated.

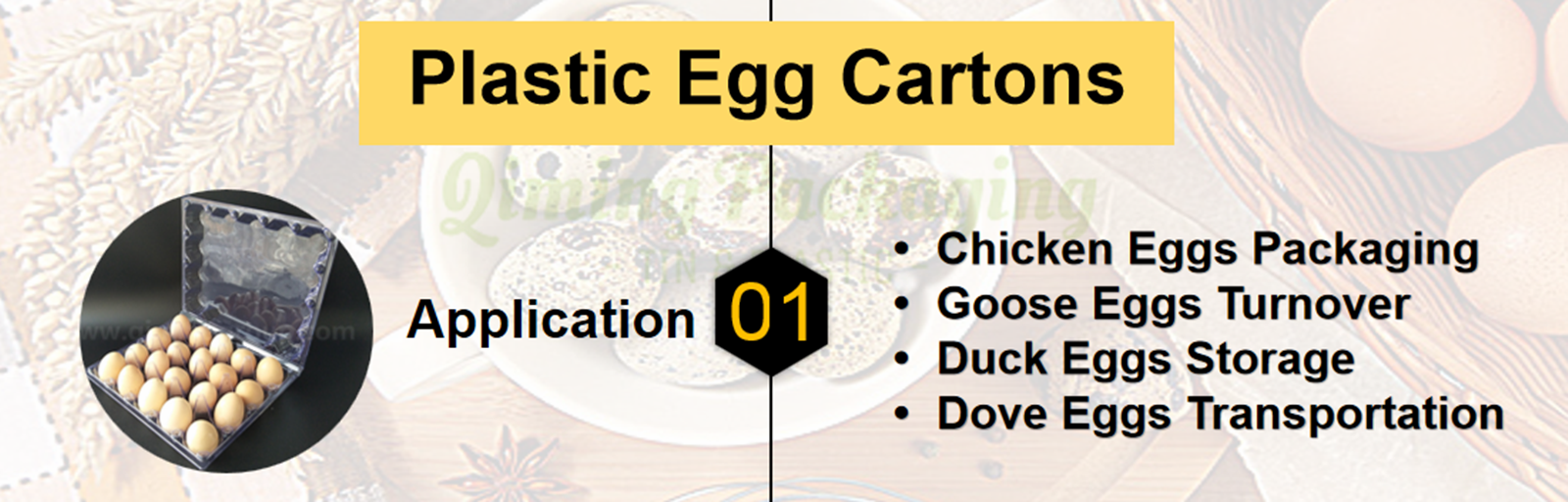

3. PVC and our product Egg Trays

Qiming Egg Trays are made of plastic, PVC with good quality.The main information is as

| Type | Size Of Tray (L*W*H) | Size Of Hole (L*W*H) |

| 6 hole egg tray | 150*102*65mm | 42*42*65mm |

| 8 holes egg tray | 198*103*65mm | 42*42*65mm |

| 10 holes egg tray | 240*102*65mm | 42*42*65mm |

| 12 holes egg tray | 292*103*65mm | 42*42*65mm |

| 15 holes egg tray | 240*150*65mm | 42*42*65mm |

| 20 holes egg tray | 240*192*65mm | 42*42*65mm |

| 12 holes quail egg tray | 138*103*36mm | 29*29*36mm |

| 18 holes quail egg tray | 198*103*36mm | 29*29*36mm |

| 20 holes quail egg tray | 168*133*36mm | 29*29*36mm |

| 24 holes quail egg tray | 198*133*36mm | 29*29*36mm |

| 30 holes quail egg tray | 198*163*36mm | 29*29*36mm |